Slash Expenses Secrets to Low Plastic Product Costs

If you're eager to slash your expenses on plastic products, now is the perfect time to browse options and discover valuable insights on how to effectively reduce costs without compromising quality.

Understanding the Cost Dynamics of Plastic Products

Plastic products are ubiquitous in modern manufacturing, offering versatility and durability. However, the cost of producing these items can vary widely depending on several factors. The price of raw materials, such as crude oil and natural gas, significantly impacts plastic production costs. Additionally, the complexity of the manufacturing process and the scale of production can influence pricing. By understanding these dynamics, you can strategically navigate the market to find cost-effective solutions.

Leveraging Bulk Purchasing for Cost Savings

One of the most effective strategies to reduce expenses on plastic products is through bulk purchasing. Many suppliers offer discounts for large orders, which can dramatically lower the per-unit cost. For instance, businesses that consistently require high volumes of plastic components can negotiate better terms and secure favorable pricing. This approach not only reduces costs but also stabilizes supply chains, ensuring that you have the necessary materials when needed.

Exploring Alternative Materials

As sustainability becomes a priority, exploring alternative materials can be both cost-effective and environmentally friendly. Bioplastics, for example, are derived from renewable sources and can sometimes offer a competitive price point compared to traditional plastics. While the initial cost might be higher, the long-term benefits of using sustainable materials can include enhanced brand reputation and compliance with environmental regulations, which can translate into cost savings over time.

Optimizing Manufacturing Processes

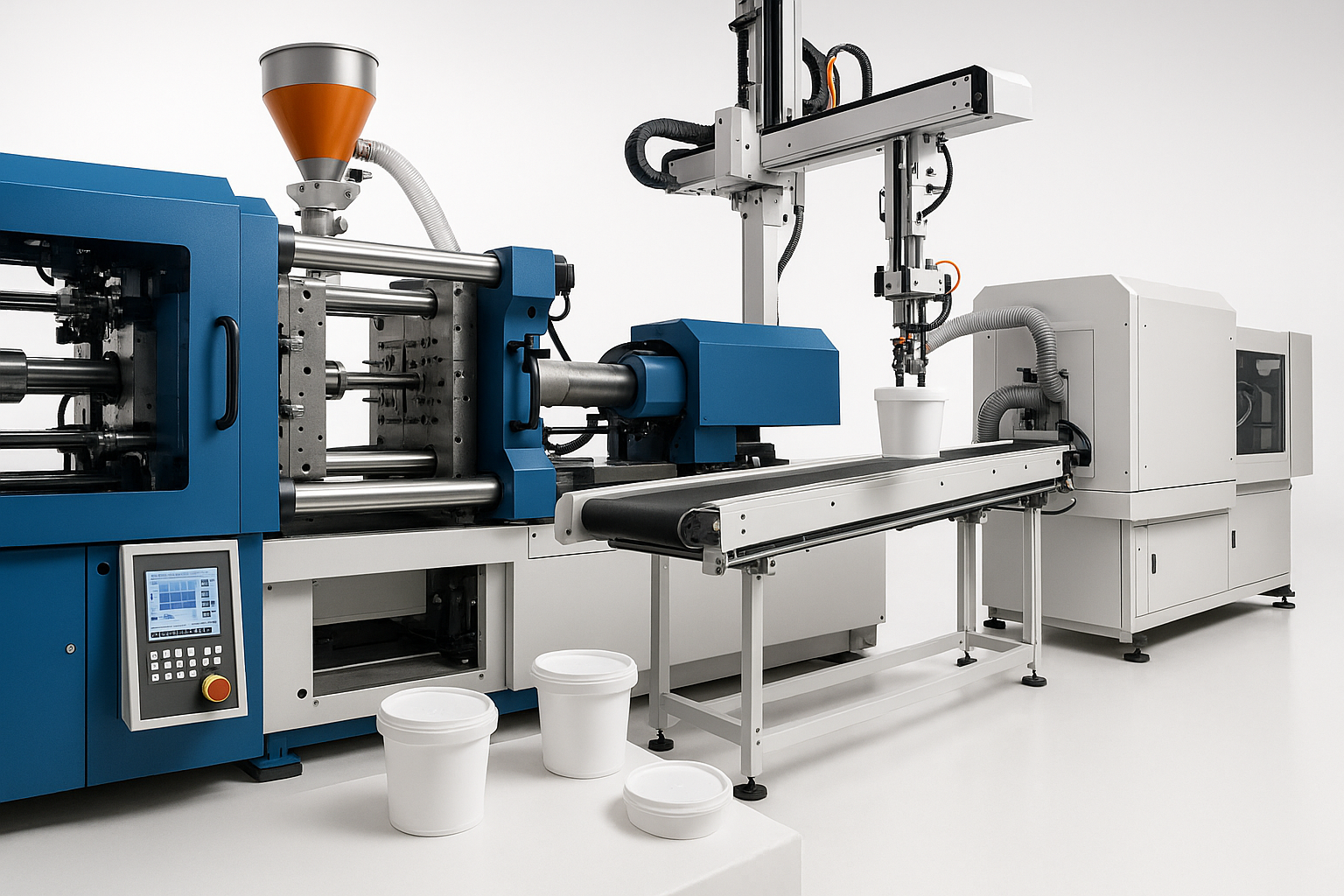

Efficiency in manufacturing processes is another critical area where cost savings can be achieved. By investing in advanced technologies such as automation and precision machinery, companies can reduce waste and improve production speed. This not only cuts down on material costs but also decreases labor expenses. Implementing lean manufacturing principles can further streamline operations, ensuring that resources are used efficiently and effectively.

Negotiating with Suppliers

Building strong relationships with suppliers can open doors to better pricing and terms. Regular communication and collaboration can lead to customized solutions that meet your specific needs. For example, some suppliers might offer flexible payment terms or loyalty discounts for repeat customers. By actively engaging with suppliers, you can identify opportunities for cost reductions and ensure a steady supply of quality products.

Staying Informed on Market Trends

Keeping abreast of market trends and price fluctuations is crucial for making informed purchasing decisions. By monitoring industry reports and market analyses, you can anticipate changes in raw material costs and adjust your procurement strategies accordingly. Websites and trade publications often provide valuable insights into market dynamics, enabling you to make proactive decisions that can lead to significant cost savings.

References

By implementing these strategies, you can effectively manage and reduce your plastic product expenses, ensuring that your business remains competitive and sustainable. As you explore these options, remember that the key to success lies in staying informed and adaptable in a rapidly changing market.