Cut Manufacturing Costs Negotiating Power Contracts Like Pros

Cutting manufacturing costs by negotiating power contracts like a pro can significantly enhance your bottom line, and by browsing options and visiting websites, you can unlock valuable insights and strategies tailored to your needs.

Understanding Power Contracts in Manufacturing

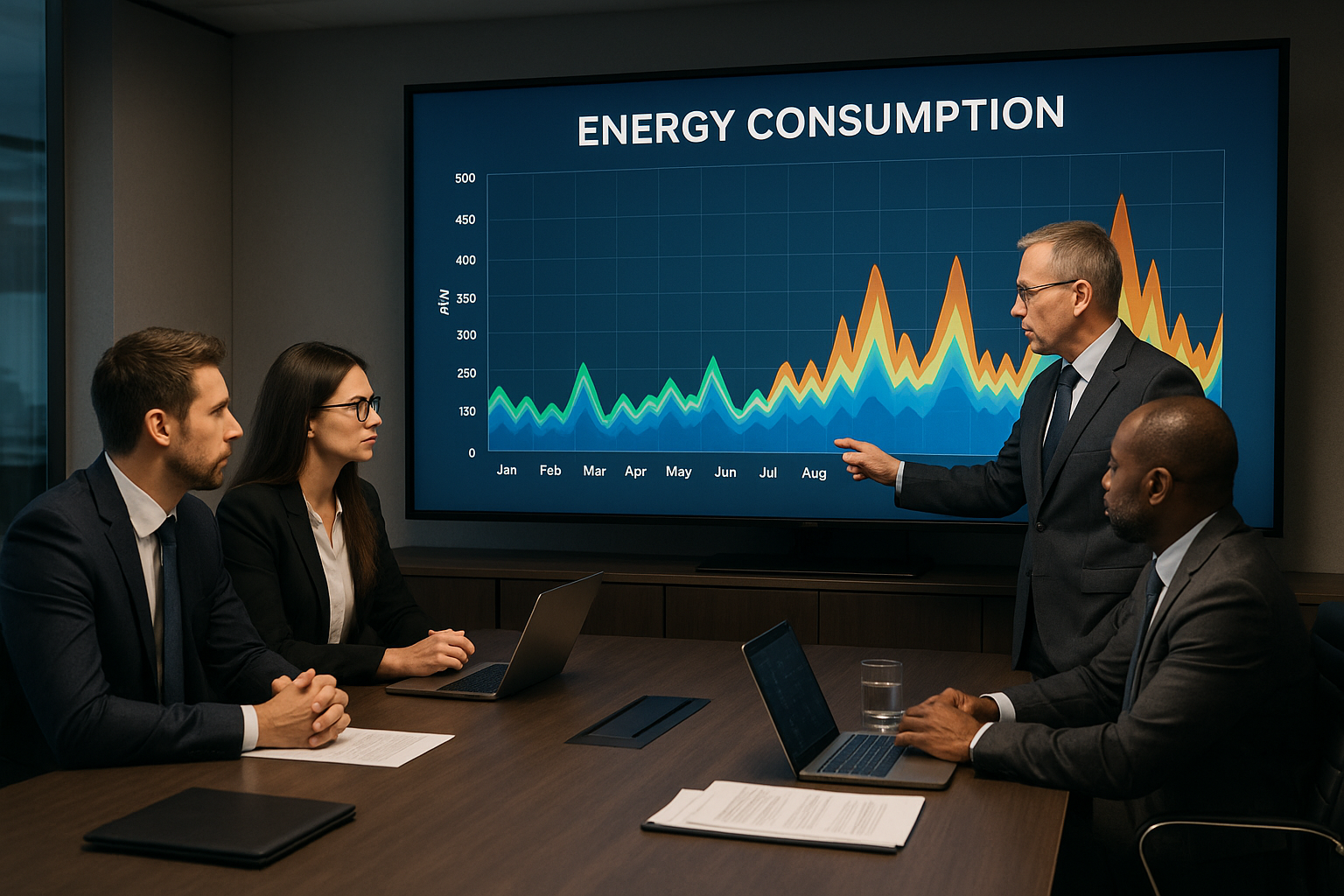

In the manufacturing sector, energy costs can account for a substantial portion of operational expenses. Power contracts, which are agreements between energy suppliers and consumers, play a crucial role in determining these costs. By negotiating these contracts effectively, manufacturers can secure favorable terms that reduce expenses and improve profitability.

Key Elements of Power Contracts

Power contracts typically include several critical components: pricing terms, contract duration, and usage stipulations. Pricing terms may be fixed or variable, with fixed rates offering price stability and variable rates allowing potential cost savings if market prices fall. The contract duration can range from short-term (1-2 years) to long-term (5-10 years), impacting flexibility and pricing. Usage stipulations define how much energy a company commits to purchasing, with penalties often applied for significant deviations from agreed usage levels.

Strategies for Negotiating Power Contracts

To negotiate power contracts like a pro, manufacturers should:

1. **Conduct a Thorough Market Analysis**: Understanding current energy market trends and forecasts is crucial. By analyzing market data, manufacturers can time their contract negotiations to coincide with favorable market conditions, potentially securing lower rates.

2. **Leverage Competitive Bidding**: Engaging multiple energy suppliers in a bidding process can drive competition and result in better contract terms. By comparing offers, manufacturers can identify the most cost-effective option.

3. **Consider Energy Efficiency Initiatives**: Implementing energy efficiency measures can reduce overall consumption, strengthening the negotiating position. Suppliers may offer incentives for companies committed to reducing energy usage, leading to more favorable contract terms.

4. **Engage Professional Negotiators**: Hiring experts with experience in energy contract negotiations can be a worthwhile investment. These professionals understand the nuances of contract terms and can identify opportunities for savings that may be overlooked.

Real-World Examples and Benefits

Several companies have successfully reduced manufacturing costs through strategic power contract negotiations. For instance, a study by the U.S. Department of Energy found that firms implementing energy management practices saved an average of 5-10% on energy costs1. Additionally, companies that adopted competitive bidding strategies reported savings of up to 15% on their energy expenses2.

Exploring Specialized Services

For manufacturers seeking tailored solutions, specialized energy consulting firms offer services to optimize energy procurement strategies. These firms provide insights into market trends, assist in drafting contract terms, and facilitate negotiations. By exploring these options, manufacturers can ensure they are making informed decisions that align with their financial goals.

Maximizing Savings Through Strategic Negotiations

By understanding the intricacies of power contracts and employing strategic negotiation tactics, manufacturers can significantly reduce their energy expenses. These savings contribute directly to improved profitability and competitive advantage. As you explore your options and consider specialized services, remember that the right power contract can be a game-changer for your manufacturing operations.