Industrial Automation USA Transforms Production Challenges Into Success

Industrial automation is revolutionizing the way you tackle production challenges, offering you the chance to browse options that transform efficiency and drive unprecedented success.

Understanding Industrial Automation in the USA

Industrial automation in the United States is at the forefront of transforming production processes, offering significant advancements that address common manufacturing challenges. By integrating cutting-edge technologies like robotics, artificial intelligence, and machine learning, companies are achieving higher productivity, improved quality, and reduced operational costs. As you explore these options, the potential for enhanced competitiveness and innovation becomes evident.

The Rise of Automation Technologies

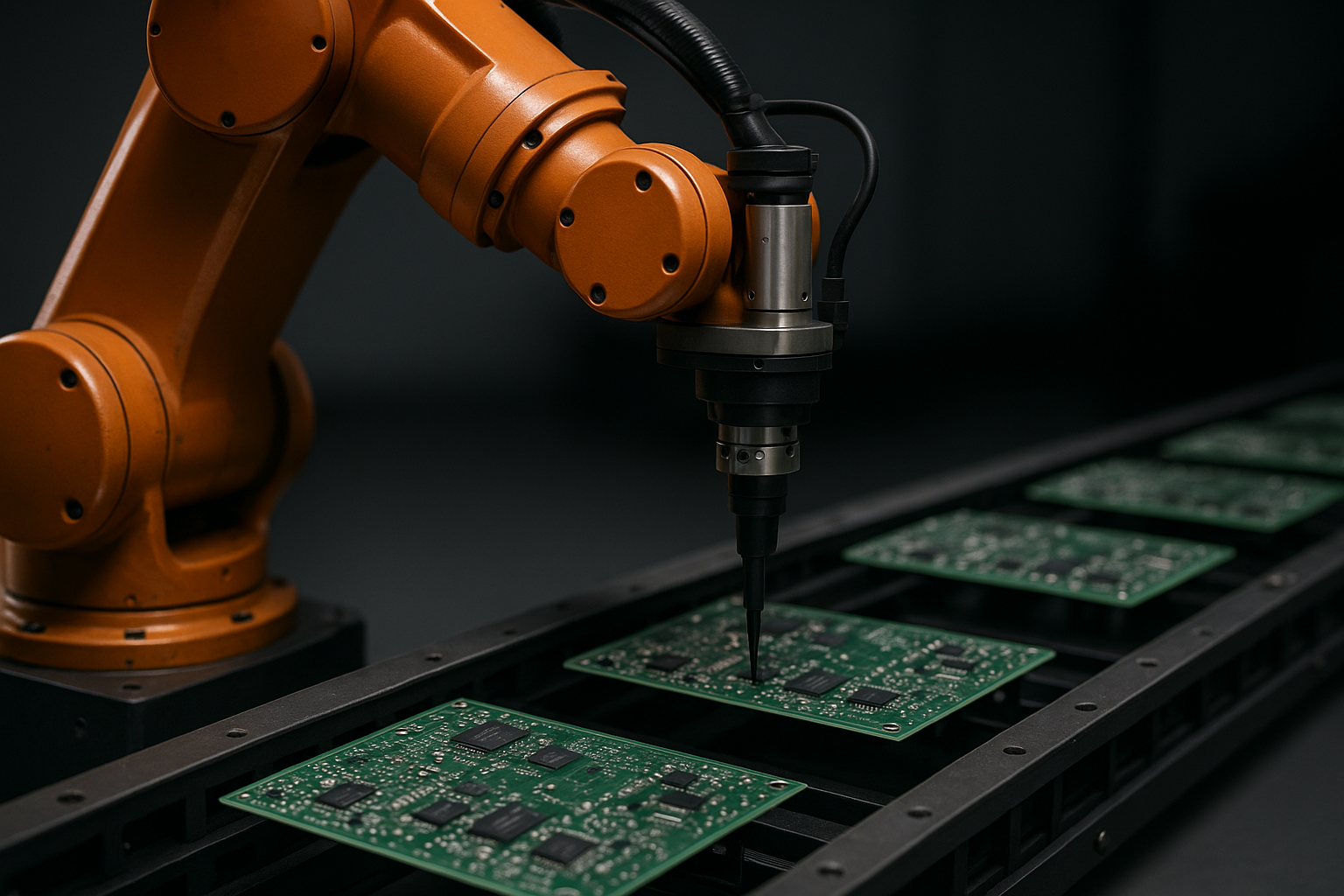

Automation technologies have evolved rapidly, with robotics leading the charge in automating repetitive tasks. According to the International Federation of Robotics, the use of industrial robots in the U.S. increased by 7% in 2022, highlighting a growing trend towards automation1. This surge is driven by the need for precision, speed, and the ability to operate in environments that are hazardous to human workers.

Economic Benefits and Cost Efficiency

One of the most compelling reasons to invest in industrial automation is the potential for cost savings. Automated systems can operate 24/7 without fatigue, significantly reducing labor costs and increasing output. A study by McKinsey & Company found that automation can cut production costs by up to 20%2. By searching options tailored to your business needs, you can find solutions that offer a quick return on investment and long-term financial benefits.

Overcoming Production Challenges

Incorporating automation can address various production challenges, such as supply chain disruptions and labor shortages. For instance, automated systems can swiftly adapt to changes in production schedules, ensuring continuity and flexibility. Furthermore, with the integration of AI, predictive maintenance becomes possible, reducing downtime and extending the lifespan of machinery3.

Real-World Applications and Success Stories

Many U.S. companies have successfully implemented automation to enhance their operations. For example, General Motors has utilized robotics to improve the precision and efficiency of its assembly lines, resulting in increased production capacity and reduced error rates4. By following the options explored by industry leaders, you too can discover innovative ways to boost your production capabilities.

The Future of Industrial Automation

The future of industrial automation promises even greater advancements, with the integration of the Internet of Things (IoT) and smart manufacturing. These technologies enable real-time data analysis and remote monitoring, providing you with deeper insights into your operations. As you visit websites dedicated to these emerging trends, you'll find opportunities to stay ahead of the curve and maintain a competitive edge.

Industrial automation in the USA is not just about overcoming production challenges; it's about transforming them into opportunities for success. By leveraging the latest technologies, you can enhance productivity, reduce costs, and position your business for growth. Explore the wealth of resources and options available, and embark on a journey towards a more efficient and profitable future.